Hot Dip Galvanized Steel

In as simple terms as possible, Hot Dip Galvanizing is the process of coating steel with a layer of zinc. Skip below to the hot dip galvanizing process.

Hot-dip galvanizing gives many benefits to the steel it protects. During the process, a multiple layered structure of steel-zinc alloys is formed between the inner surface of the zinc coating and the iron or steel. The zinc-steel alloy layers are metallurgically-bonded to not only create a barrier between the steel and the corrosive environment, but also to cathodically protect the steel. Cathodic protection means the galvanized zinc coating sacrifices itself to protect the base steel from corrosion. The zinc is has a bond strength of about 3,600 psi and is significantly abrasion-resistant, as the intermetallic layers are harder than the base steel (image 1). Even if the zinc coating was damaged, the sacrificial operation of zinc will protect exposed steel up to 1/4 inch. (7)

Image 1: Microstructure and hardness of hot dipped galvanized zinc coating

Hot Dip Galvanizing Process

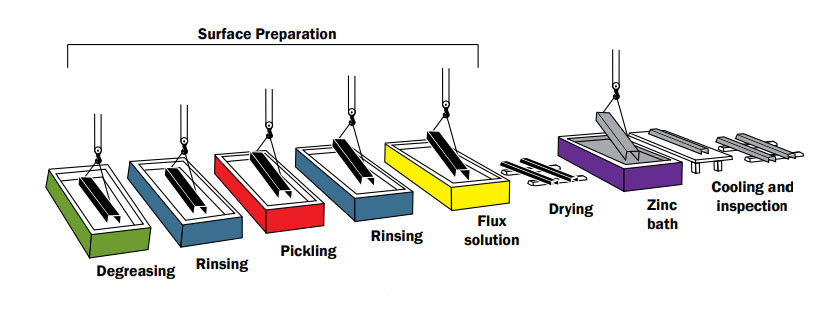

Hot dip galvanization creates a nice, thick layer of zinc on top of the base metal; making it extra resistant to corrosion. There are three steps to hot dip galvanizing: surface preparation, galvanizing, and inspection.

Figure 1: illustration of the Hot Dip Galvanizing Process

Surface Preparation

To ensure a well-crafted bond between the base metal and zinc coating, there are three cleaning steps: degreasing, pickling, and fluxing. Once grease and oil residue is removed, an acid pickling bath removes mill scale and iron oxide. The metal is fluxed to strip any remaining oxides and then the steel is coated with a protective layer so additional oxidation cannot occur before galvanizing.

Galvanizing

The base metal is dipped into molten (830 F) zinc at an angle which allows the zinc to flow into, over, and through the entire piece. The iron in the steel metallurgically reacts with the zinc and a from a succession of zinc-iron intermetallic layers and an outer layer of pure zinc.

Inspection

Newly galvanized metal is finally inspected for quality of coating and compliance with thickness requirements.

As well as providing long-term durability and protection from corrosion, a real benefit is the relatively low environmental burden associated with the whole process. Learn about the toxicity of galvanized steel. (2)

Compare properties of hot-dipped galvanized steel to electroplated galvanized steel.